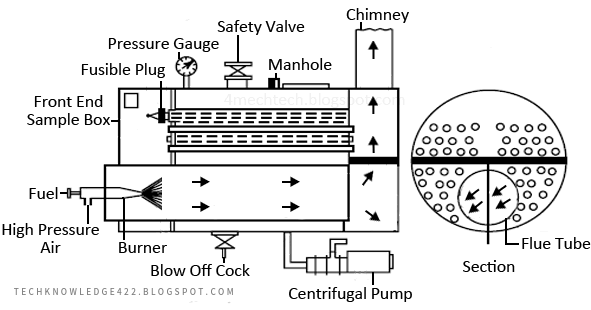

Nestler boiler is a horizontal axis fire tube boiler. The shell of the Nestle boiler consists of two thick mild steel plates. A large number of fire tubes are attached to the steel plate. Nestler boilers use large diameter furnace tubes extending from one end of the burner to the other to move hot flue gas from one smoke box to another.

To reject the exhaust gas, a smoke box or chimney is provided at the rear of boiler. The fuel used for combustion is a highly viscous fluid that is firstly heated up to 80 °C and then supplied for combustion purpose. Nestler boilers can deliver steam up to a pressure of 10-11 bar.

Main parts of Nestler Boiler:

- Pressure gauge

- Stop valve

- Safety valve

- Manhole

- Chimney

- Rear end smoke box

- Centrifugal pump

- Blow off cock

- Flue tube

- Burner

- Front end sample box

- Fusible plug

Pressure Gauge:

The function of the pressure gauge in nestler boiler is to measure the pressure of steam inside the boiler. The pressure gauge is usually mounted on the top of the shell or drum such that it should be clearly visible to the operator.

Steam Stop Valve:

Steam stop valve is used to regulate the flow of steam from one steam pipe to the other.

Safety Valve:

The function of the safety valve is to protect the boiler from the danger of pressure exceeding the safe working pressure. Each boiler has a safe working pressure designed by the manufacturer and can be operated safely if it is operated within this pressure range. The designed pressure may exceed the safe working pressure.

Manhole:

Manhole is provided on the top of the shell of the boiler to enable a man to enter into it and inspect and repair the boiler from inside of it. It is also, meant for cleaning the interior of the boiler shell and exterior of the combustion chamber and stack (chimney).

Chimney (or stack):

Blow off Cock:

Blow off cock is used to blow away impurities, sludge and sediment present in boiler water.

Fusible Plug:

The main purpose of a fusible plug is to

extinguish the fire in the furnace of the nestler boiler when the water level in the boiler falls below an unsafe level. Thus, explosion is avoided which may take place due to overheating of the tubes and shell.

Working of Nestler Boiler:

- The fuel and high-pressure air are mixed to form an air-fuel mixture which is then burned to produce hot gases.

- Hot gases passes through the furnace tube and enters the smoke box at the rear of the Nestler boiler.

- Hot gases from the rear smoke box enters the fire tube which is surrounded by liquid.

- Hot gases transfer their heat to the liquid and move forward into the front end sample smoke box from there finally hot gases moves toward the chimney from where they are eliminated into the atmosphere.

- The steam generated as a result of heat transfer between the hot gases and the water is collected in the steam chamber above.

Specifications of Nestler Boiler:

- working pressure : 0.7 bar

- Shell size : 1.6 m diameter x 3.48 m length.

- No. of tubes : 94

- Size of tube : 63.5 mm

- No. of passes : 3

- Steam space : 1.47 m3

- water space : 2.25 m3