Classification of chains:

Chains are classified into three groups, on the basis of their use :

- Hoisting and hauling (or crane) chains

- Conveyor (or tractive) chains

- Power transmitting (or driving) chains

We are going to discuss about these kind of chains, in the following article.

Hoisting and Hauling Chains:

The hoisting and hauling chains have two types which are given below :

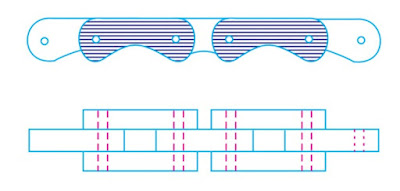

Chain with oval links:

The links of this type of chain are of oval shape, as shown in Figure. 1. The joint of each link is welded. The Sprockets used for this type of chain contain receptacles to obtain links. Such chains are used only at low speeds, such as when loosening chains and in anchors for marine work.

Chain with square links:

The links of this type of chain are of square shape, as shown in Figure. 2. Such chains are used in hoist, crane, dredge. The production cost of this type of chain is lower than that of a chain with oval links, but in these chains, kinking is easy on overloading.

Conveyor Chains:

These chains are used to continuously lift and deliver materials. There are two types of conveyor chains:

- Detachable or hook joint type chain, as shown in Figure 3.

- Closed joint type chain, as shown in Figure. 4.

Conveyor chains are usually made of malleable cast iron. These chains do not have smooth running points. Conveyor chains run at a slow speed of about 3 to 12 km.p.h.

Power Transmitting Chains:

These chains are used for power transmission when the distance between the centers of the shafts is short. These chains have provision for efficient lubrication. The power transmitting chains are of the following three types.

Block chain:

A block chain, as shown in Figure. 5. is also known as bush chain. Given type of chain was used in the early stages of development in the power transmission.

Rubbing between the teeth and the links makes a noise when the sprocket’s teeth come close or leave. Such chains are used to some extent as carrier chains.

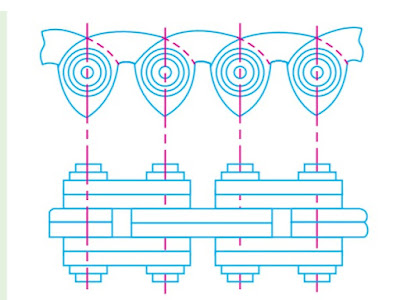

Bush roller chain:

A bush roller chain, as shown in Figure. 6, consists of outer plates or pin link plates, inner plates or roller link plates, pins, bushes and rollers. A pin passes through the bush which is secured in the holes of the roller between the two sides of the chain. The rollers are free to rotate on the bush which protects the teeth of the sprocket wheel from wear.

The bush roller chain is extremely strong and simple to build. It serves well in critical situations. There is a slight noise with this chain due to the effect of the rollers on the teeth of the sprocket wheel. This chain can be used where there is little lubrication. When one of these chains expands slightly due to wear and stretching, the extended chain has a higher pitch than the tooth pitch of the sprocket wheel. The rollers then fit unevenly into the wheel cavity. The result is that the total load falls on one tooth or a few teeth. The stretch of the parts extends to the surface of the roller and the teeth of the sprocket wheel.